Bogie Skidder - 768L-II

- Gross Power: 210 kW (281 hp)

- Gross Torque: 1276 Nm (941 ft.-lb.)

- Max. Grapple Capacity: 2.07 m2 (22.3 sq. ft.)

- Operating Weight: 23 697 kg (52,245 lb.)

Features

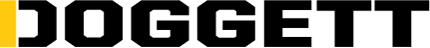

Continuously Variable Transmission (CVT) used in L-II skidders

Continuously Variable Transmission (CVT) used in L-II skidders

Overview

Offering loggers the best of both worlds, the Continuously Variable Transmission (CVT) combines the efficiency of the direct-drive transmission with the smoothness and ease of a hydrostatic drive.

Delivering efficient power to the ground, the CVT automatically senses the load before delivering more torque to maintain the operator's wanted speed.

The CVT also eliminates the need to shift gears, which shortens the learning curve for new operators, and helps the experienced pros maximize productivity.

Benefits

- Constant engine speed helps provide superb multifunction performance

- Easy to operate, especially for new operators

- Defined ground speed limiters allow you to control your operating speed

- No need to shift gears

Mobile device using JDLink™

Mobile device using JDLink™

Machine Health Monitoring Center

Machine Health Monitoring Center

TimberMatic™ Maps monitor displaying live production data

TimberMatic™ Maps monitor displaying live production data

Overview

Now included in base machine, the JDLink telematic system provides the foundation for John Deere’s Precision Forestry solutions. These systems help optimize your machine, your uptime, and your jobsites, which ultimately lead to improved production efficiency.

Benefits

- JDLink connectivity enables you to view several parameters of your machine, including its location, fuel level, average fuel burn rate, idle time, machine utilization, and much more

- John Deere Connected Support™ allows the dealer to provide remote diagnostics, rapid service response with the right part in hand, and parts availability; all to maximize machine uptime

- John Deere’s centralized Machine Health Monitoring Center analyzes data from thousands of connected machines, identifies trends, and develops recommended actions to help prevent downtime

- Optional TimberMatic Maps gives enhanced visibility to the jobsite, which streamlines communication and increases efficiency

- TimberManager™ provides remote visibility to your operation from any device, allowing you to make smart business decisions based on real-time production data

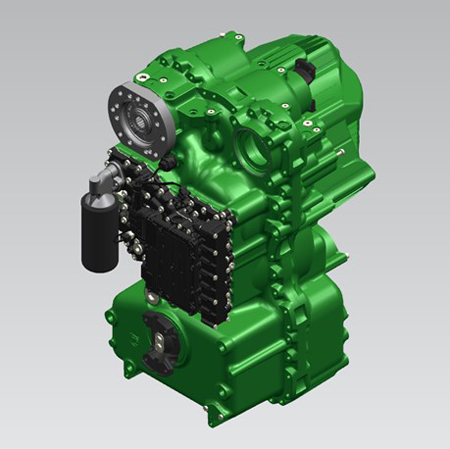

Removable engine panels and swing out coolers

Removable engine panels and swing out coolers

Optional electric pump for filling hydraulic fluid

Optional electric pump for filling hydraulic fluid

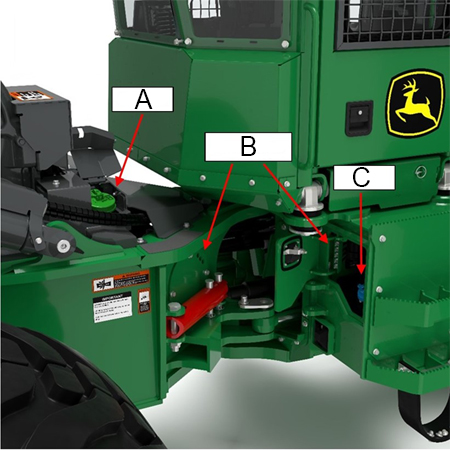

Fuel and diesel exhaust fluid (DEF) fills located on the same side of the machine. Grease banks are also located near the DEF fill.

Fuel and diesel exhaust fluid (DEF) fills located on the same side of the machine. Grease banks are also located near the DEF fill.

- Diesel fill

- Grease banks

- DEF fill

Overview

Easy access to service components helps confirm daily checks and perform any scheduled maintenance, which ultimately minimize unexpected downtime and costly repairs down the road. The L-II lineup of skidders feature removable engine panels for wide-open access to filters and fluid level checks. Swing out cooler doors and an automatic reversing fan provide effortless cleaning of debris from the coolers. Fluid fills including fuel, DEF, and hydraulic oil can all be easily accessed from ground level, as well as daily greasing points.

Benefits

- Ground level daily maintenance

- Swing out coolers for quick and easy cleaning

- Detachable engine panels

- Remote diagnostics via John Deere Connected Support

- Wiring and hose routings are protected against debris intrusion

- Simplified routing of the electrical and hydraulic systems

- Extended filter-change interval for hydraulic filter service

768L-II reaching high with a load of timber

768L-II reaching high with a load of timber

Overview

A long wheelbase and large grapple working area boosts reach and lift capability, for increased dexterity in the woods. Combined with a tight turning radius, the 768L-II enhances agility at the landing and in tight working areas.

Benefits

- Ability to lift loads higher and reach further, compared to 4-wheeled skidders

- 6% tighter turn radius compared to leading competitors**

- ~60% larger grapple working area compared to leading competitors**

** Compared to Tigercat 625E

Sail operating area on a 768L-II

Sail operating area on a 768L-II

- Sail operating area = 4.8m2 (52 ft²)

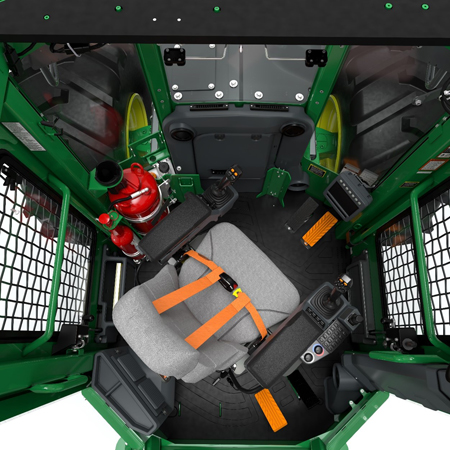

240-degree rotating seat with electrohydraulic (EH) joystick controls

240-degree rotating seat with electrohydraulic (EH) joystick controls

Overhead view of the operator station

Overhead view of the operator station

Rear facing visibility on a 768L-II

Rear facing visibility on a 768L-II

Overview

Designed by loggers for loggers, the quiet, spacious cab helps keep you more comfortable and productive – so you can boost your bottom line.

The 4 m2 (43 ft2) of window area, coupled with the 240-degree rotating seat, maximizes visibility to the task at hand while minimizing neck strain. Armrest-mounted electrohydraulic (EH) joysticks provide smooth and intuitive control of all machine functions at your fingertips.

The EH joysticks also allow you to customize the button and lever layout to your preference and saves your settings when switching between operators.

Benefits

- Large windows provide clear visibility to the drag

- Rotating seat allows you to operate the machine while facing the front or rear

- Optional light-emitting diode (LED) lights allow you to start earlier and work later

- Customizable joystick patterns for multiple operators

- Optional heated seat with leather trim

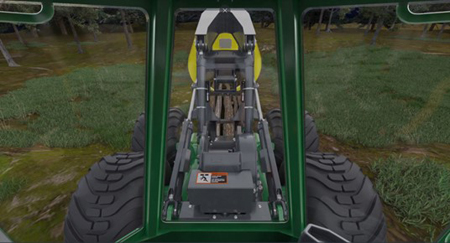

Bogie axles on a 768L-II

Bogie axles on a 768L-II

768L-II bogie skidder maneuvering over a stump

768L-II bogie skidder maneuvering over a stump

Overview

The purpose-built bogie axles on the 768L-II provide greater traction and flotation, compared to a 4-wheel skidder, which enables you to continue working in challenging ground conditions. The Permanent Bogie Balancing System® (PBBS) keeps both bogie tires firmly in contact with the ground, while also evenly distributing the weight of the load when travelling over obstacles. Independently oscillating bogie axles reduce machine vibration to deliver a comfortable and smooth ride.

Benefits

- Increased stability and traction, especially on steep slopes

- Increased flotation for challenging ground conditions

- Independent side to side bogie oscillation of +/- 40 degrees

- Improved operator comfort, compared to a 4-wheel skidder

- Integrated bogie axle cooling circuit