Tracked Harvester - 803MH

- Net Power: 224 kW (300 hp) at 1,900 rpm

- Max. Boom Reach: 9.91 m (32 ft. 6 in.)

- Tractive Effort: 245 kN (55,040 lbf)

Features

Inside the cab of a 953M

Inside the cab of a 953M

Floor-to-ceiling front window

Floor-to-ceiling front window

Operating for long hours is common. As the day goes on, maintaining consistent productivity is important. One factor in keeping high, consistent productivity is a comfortable operating environment. The M-series boasts greatly increased window area for better visibility and more cab space over prior models. Low-effort electrohydraulic (EH) controls allow you to customize the button and lever layout to your preference and save your settings when switching between operators.

- Large and spacious operator station designed with operator input

- Ergonomic controls and increased cab volume over prior models

- Floor-to-ceiling front window, large side windows, skylight, and optional floor window (standard on leveling machines) significantly expands operator visibility

- Optional heated and ventilated seat

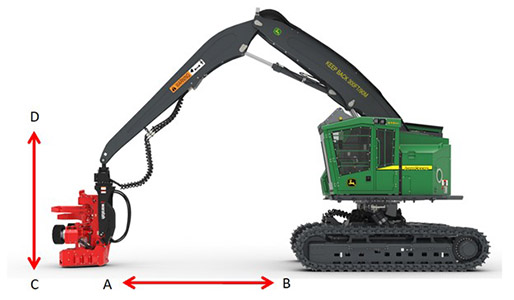

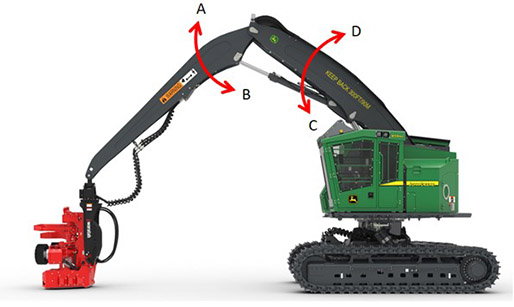

Boom control pattern with IBC

Boom control pattern with IBC

Boom control pattern without IBC

Boom control pattern without IBC

Boom joystick pattern

Boom joystick pattern

With IBC |

Without IBC |

|

A |

Extend |

Stick out |

B |

Retract |

Stick in |

C |

Lower |

Hoist down |

D |

Raise |

Hoist up |

Intelligent Boom Control (IBC) smooths boom operations, making them more precise and efficient, to increase operator productivity compared to a Deere tracked harvester without IBC. With IBC, you no longer need to control each boom function independently. Just control the direction of the head with a single lever command, and IBC will automatically guide the boom and cylinders accordingly. IBC also utilizes adaptive swing control to adjust the swing speed based on the overall position of the head. This makes controlling the head more precise and intuitive, especially for new operators, compared to machines without IBC.

- Customizable control pattern and boom motions

- More efficient and consistent boom movements

- Enhanced cylinder cushioning reduces shock loading at end-of-stroke

- Overall improved operator experience

- Simple and intuitive to operate

Mobile device using JDLink™

Mobile device using JDLink™

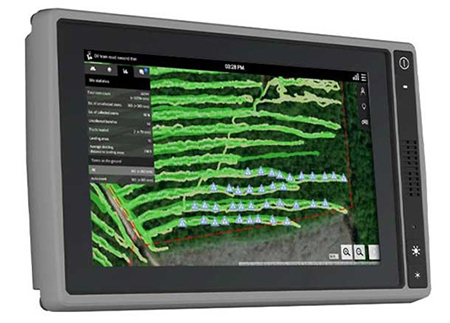

TimberMatic™ Maps monitor displaying live production data

TimberMatic™ Maps monitor displaying live production data

Machine Health Monitoring Center

Machine Health Monitoring Center

Now included in base machine, the JDLink telematic system provides the foundation for John Deere’s Precision Forestry solutions. These systems help optimize your machine, your uptime, and your jobsites, which ultimately lead to improved production efficiency.

- JDLink connectivity enables you to view several parameters of your machine, including its location, fuel level, average fuel burn rate, idle time, machine utilization, and much more

- When enabled, John Deere Connected Support™ allows the dealer to provide remote diagnostics, rapid service response with the right part in hand, and parts availability; all to maximize machine uptime

- John Deere’s centralized Machine Health Monitoring Center analyzes data from thousands of connected machines, identifies trends, and develops recommended actions to help prevent downtime

- TimberMatic Maps gives enhanced visibility to the jobsite, which streamlines communication and increases efficiency

- TimberManager™ provides remote visibility to your operation from any device, allowing you to make smart business decisions based on real-time production data

An operator stands on the enclosure platform to service the engine

An operator stands on the enclosure platform to service the engine

Service doors and enclosure open on an 853M

Service doors and enclosure open on an 853M

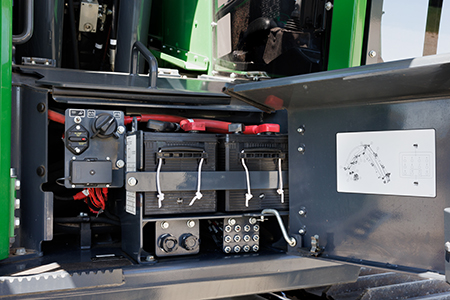

A grease bank is located near the battery disconnect, to easily service the boom joints

A grease bank is located near the battery disconnect, to easily service the boom joints

The rear service ladder provides access to the diesel fuel and diesel-exhaust fluid (DEF) fills

The rear service ladder provides access to the diesel fuel and diesel-exhaust fluid (DEF) fills

Easy access to service components helps operators perform daily checks and any scheduled maintenance, which helps minimize unplanned downtime and costly repairs down the road. The 800M-series tracked machines feature a fully opened enclosure and service doors for excellent access to all scheduled maintenance areas.

- Smart debris management designed to keep your workspace free and clear

- Variable-speed reversing fan helps minimize debris build-up in the cooling package

- Swing-out doors provide wide-open access to the cooling package

- Optional vacuum pump for convenient servicing of hydraulic components

- Grease banks for servicing hard-to-reach joints

- Large fuel tank extends intervals between fill-ups

- Remote diagnostics and machine monitoring with JDLink™

U7 undercarriage

U7 undercarriage

The M-series undercarriage is purpose built to handle severe forestry applications while maintaining maneuverability, especially in thinning operations. The track frames are shaped to deflect debris while also providing strength and stability.

- Long, wide undercarriage provides solid balance to maximize stability

- Exceptional tractive effort for negotiating difficult or steep terrain, deep snow, and swamps

- Optional closed-loop hydrostatic drive on 800M/MH models for increased multifunctioning performance

- Various track pad widths and grouser types are offered to best suit the machine to its application

- Optional tri-track helps prevent premature wear due to track twisting